The Roadrunner ERP Expansion Pack

Improves management visibility and operational synchronization

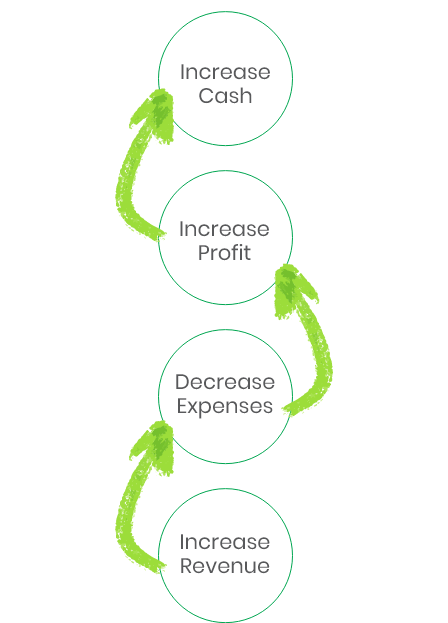

Dramatically increase productivity, revenue and profit

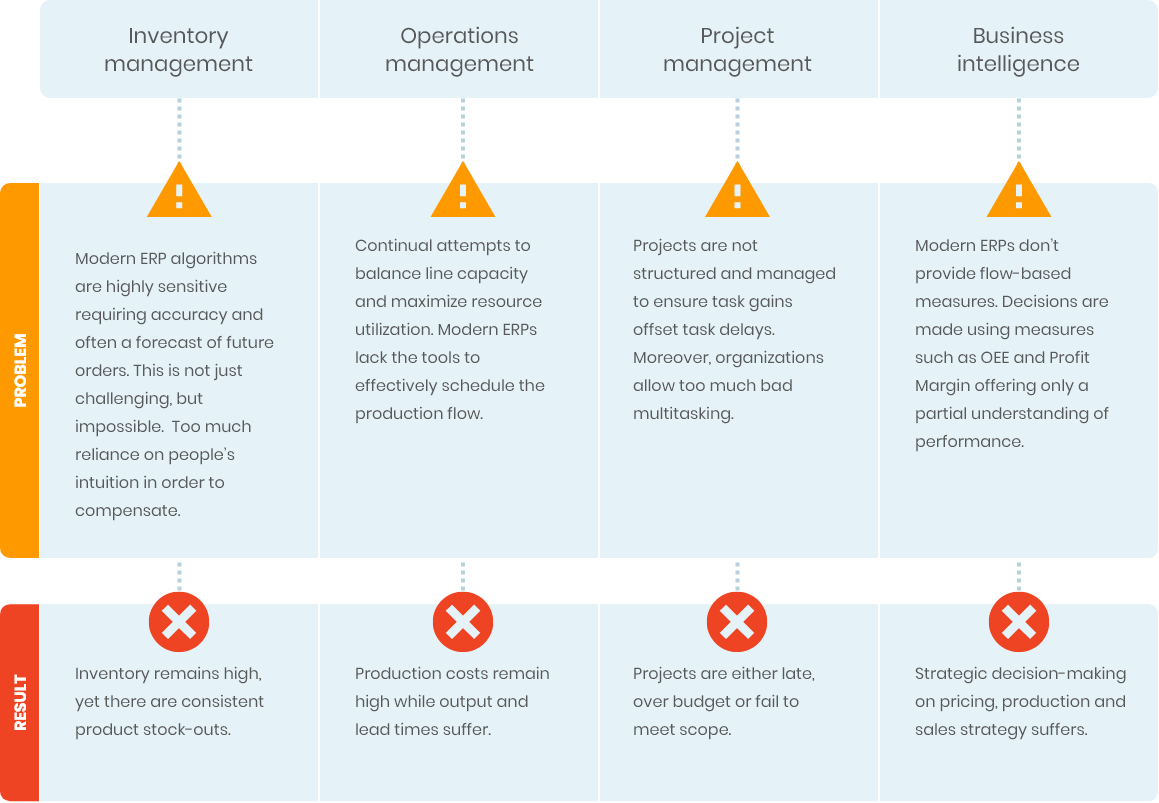

Many manufacturers find their ERP (and MRP) fails at delivering on key expectations — inventories don’t drop, lead times don’t improve and operational costs remain stubbornly high.

roadrunner ERP Expansion Pack can help you finally get real results.

Turbocharge your ERP

with Theory of

Constraints technology

This suite of four plugins — used individually or in concert — solve stubborn problems in operations and your supply chain, accelerate project execution and give you the insights needed to maximize sales and profitability.

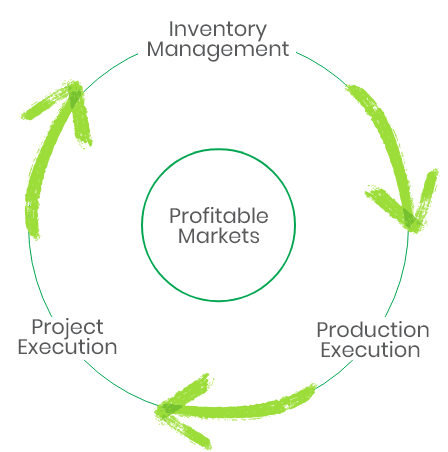

Create better operational and financial performance

roadrunner is the foundation for a Flow Management System (FMS) that maximizes revenue and profitability

roadrunner Focus

Business Benefit

Financial Impact

Works with all popular ERPs

![]()

![]()

Leverage the power of TOC thinking and processes as first explored by Eli Goldratt in The Goal.

The roadrunner ERP Expansion Pack

Four plugins. Simply bolt onto your ERP and go.

-

PLUGIN

roadrunner Rx for Inventory Management

Reduce inventory levels and cost while growing sales More -

PLUGIN

roadrunner Mx for Production Management

Increase plant capacity and throughput More -

PLUGIN

roadrunner Px for Project Management

Deliver more projects, faster More -

PLUGIN

roadrunner Bx for Business Intelligence

Monitor and maximize profitability More

roadrunner Rx

for Inventory Management

- Better item availability

- Lower operating costs

- 25% inventory reduction

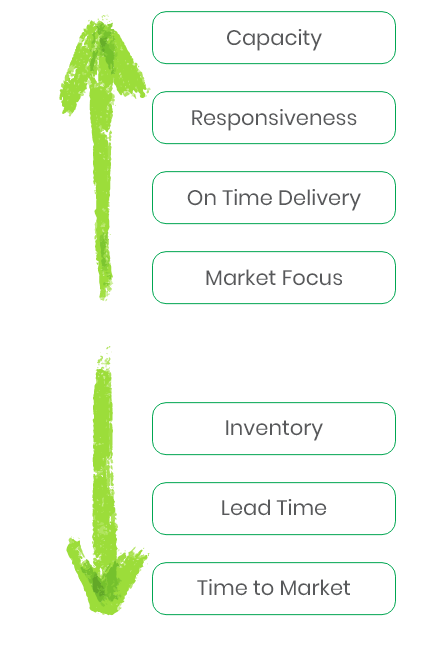

Modern MRP algorithms are highly sensitive. They require accuracy and, often, a forecast of future orders. The problem is that achieving accuracy and a reliable forecast is not just challenging. It’s impossible. roadrunner Rx is a simple fix to improve stock availability, lower operating costs and rein in excess inventory by 25% (or even more).

roadrunner Rx uses an algorithm that draws on the well-established principles of Demand-Driven Replenishment (DDR).

DDR doesn’t use forecasting. It accounts for changing customer orders, as well as unreliable plant and supplier performance, and wholly removes the need for operator/management guesswork.

roadrunner Rx

Key Functionality

• Design and Manage Raw Materials and Finished Goods Buffer Inventories

• Communicate Daily Order Requirements - “What to Buy & Make”

• Monitor Supply Chain Pipeline Status (ensure right supply)

• Design and maintain Inventory Performance Scorecard

• Evaluate Vendors and Purchasing Team’s Performance

• Generate slow and non-moving inventory reports

• Create Purchase Order Expedite List

roadrunner Mx

for Production Management

- Reduce lead times 50%

- On-time delivery up to 99%

- Produce 20% more with same resources

Standard production- practices are responsible for the operational problems they purport to solve. Poor OTD. Fire-fighting. Regular schedule replanning. Inflated WIP and rework.

roadrunner Mx is a plugin that applies the three simple rules of Drum-Buffer-Rope to solve these pervasive production problems. roadrunner Mx makes it easy to determine in real-time what to produce, how to sequence the production flow while synchronizing the material release. In addition, roadrunner Mx enables the Continuous Improvement process by monitoring and prioritizing what you need to fix to make it all happen on time.

Quickly see which orders are the priority, how long they should take to reach your production bottleneck, and whether there are any other issues with an order.

Deploying roadrunner Mx means you can produce more with the same resources and increase plant capacity by as much as 20%.

roadrunner Mx

Key Functionality

• Analyze what-to-buy, what-to-make, and what-to-ship

• Synchronize the schedule with material requirements

• Obtain 100% visibility of work flow, priorities and production issues

• Automate release of orders and flow issue reporting

• Reconcile make-to-order and make-to-stock work production priorities

• Simplify production, quality and issue reporting

• Drive continuous improvement processes

• Measures plant performance

roadrunner Px

Project

Management

- Reduce project cost and duration

- Increase pipeline capacity by 25%

- Deliver on time and budget

Most projects are late, over budget and under scope. Yet the science of project management has scarcely changed in 60 years — until Critical Chain.

roadrunner Px is an ERP plugin that applies Critical Chain to your project management to prioritize tasks and resources in real time, resolve conflicting priorities, and reduce bad multi-tasking.

Ensure task gains offset task delays and facilitate full kitting while improving quality and minimizing rework. And view the priority of active projects to determine which project needs the most attention using the ratio of Critical Chain complete to Project Buffer consumed.

With roadrunner Px, it’s possible to deliver projects 25% to 40% faster while getting through 25% to 50% more than you thought feasible.

roadrunner Bx

for Business Intelligence

- Optimize product mix for max revenue

- Determine best pricing

- Leverage business intelligence

Most manufacturers use conventional cost accounting. Yet it’s completely unsuited to what they do, and invariably supplies an incorrect picture of the strategic strengths and weaknesses of the business! roadrunner Bx leverages the power of Throughput Economics to accurately measure the operational performance for fast, informed decision making on how to set pricing and product mix to maximize profit from sales.

Simple dashboards, based on operations and sales data cubes, generate customizable key performance indicators (KPIs). These critical measures highlight how well the company is satisfying its customers and what is preventing the business from increasing profit.

Fully leverage your ERP today

Engineered from the ground-up by experts in TOC, Lean and Six-Sigma, this ERP Expansion Pack is designed to help manufactures and distributors fully leverage the power of their ERP without requiring dramatic change.

Let us simulate your inventory with roadrunner Rx

Simply provide us the inputs for your last 12 months of transactions. We’ll model your material requirements and compare it to actuals using roadrunner Rx. We’ll then show you the difference in what you should have ordered versus what you did.

It’s the fastest, easiest way to gauge just how roadrunner Rx can help your company, and the potential savings and improvements to cashflow.

Request Rx simulation

Submit a request and we’ll be in touch to organize the details of your simulation.